contact us

contact us

If you would like to leave us a comment please go to

Contact Us

Many stamping parts manufacturing company use steel sheet instead of the coil for stamp parts because of process requirement.Many companies order steel sheet from steel processing companies.It makes troubles as below:

1. The traditional cut to length line (CTL) cost is too high.

2. The traditional cut to length line (CTL) is not flexible. When the production quantity is small, they need to order from the supplier frequently. It lost time and cost. It makes the production organization more difficult. And also lost customers` satisfaction.

So many stamping parts companies want to get their own cut to length line (CTL). But, generally, in the market, cut to length line (CTL) is a big line. To meet the flexible requirement, the big line is too heavy, it has 2 big pits, it’s expensive. The line utilization is less.

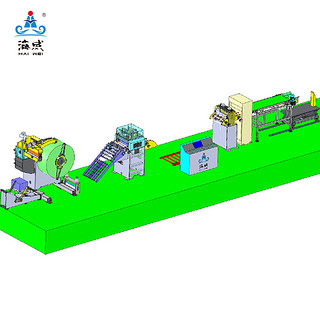

Our solution is to make an economic cut to length line (CTL), which is made up of uncoiler, straightener, feeder, shearing machine, conveyor and economic stacking system. To get more high speed, the uncoiler is designed a big loop, and straightener is driven by the servo motor. The max line speed can achieve 60m/min. It's most suitable for sheet steel application’s company, with lower cost, good flexibility (no pit) and not bad speed. It's popular all over the world.

If you want to learn more about us, please contact us, we will give the best service for you.